So we are finally stepping on the gas for this project. It’s crazy how many times we have made plans and changed them in the last 8 months. I am not even sure of our plans now, but its build time so here we go.

Our custom trailer was made by Fleming Trailers in Glendale, Arizona. They did an amazing job and the only way it could be better is if I knew more about what I needed beforehand. Darn hindsight! I will make some diagrams to explain what I would do differently at a later date because they are very small changes that might not even apply to everyone. For now, the pictures…

You can tell that building the frame out to the edges of the wheels is something we added that you don’t see in typical Tumbleweed or other trailers for tiny homes. My intention is this will eliminate the need for a subfloor to be built with conventional framing lumber since now we can insulate inside the trailer frame without having a gap in our thermal envelope.

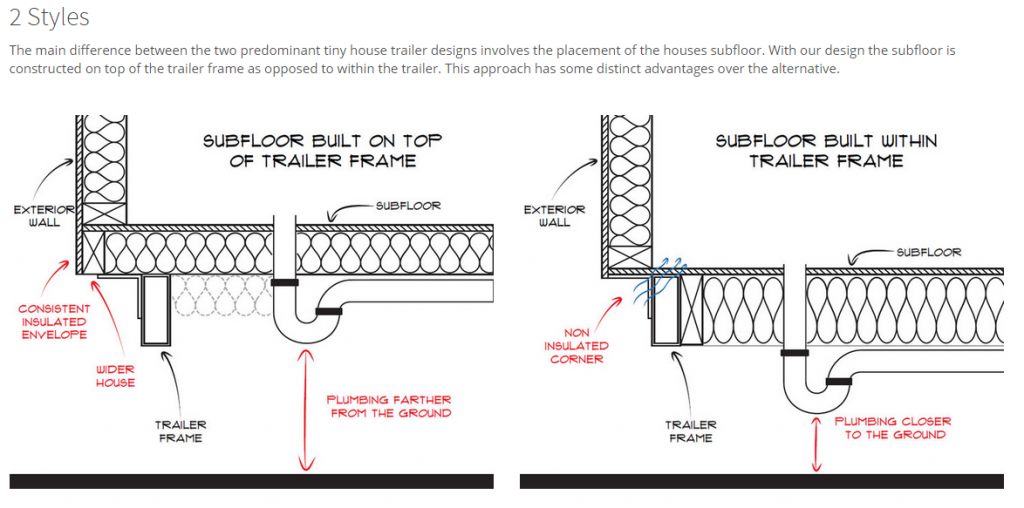

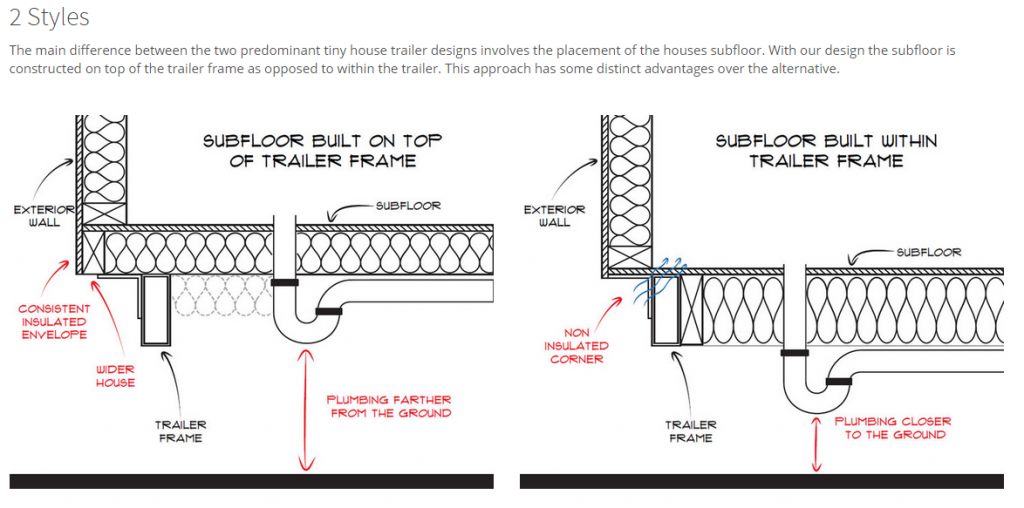

My understanding of this comes from here: http://www.tinyhomebuilders.com/tiny-house-trailers/trailerdifferences

They explain how the subfloor and insular envelope works. But I think a third option is missing from the diagram below, namely having the frame reach the edges and plumbing inside the frame.

If the trailer frame can reach the very edge of the build width, then you don’t have that troublesome corner(image right). As for the plumbing being lower to the ground, our trailer crossbeams create some cavernous spaces where inside the floor there can still be pipes along with the insulation and it should not be a problem. I have a very experienced plumber on staff (my father) who can verify this.

I was very excited to hear this because now this gains a few more inches of room for the interior height.

Now our trailer dimensions:

- Width 8’6″

- Deck Height(loaded) 20″

- Length 20′

- Wheel Wells – 66″ L x 11″ W x 1′ H centered at 130″ back from the front of the trailer

I include the wheel well dimensions because they make a big impact when you are not building a deckover style trailer, or building the sub-floor up high enough to be level with the tops of the wells so that you don’t see them.

That’s all for now, I will be starting a budget page next to keep track of what everything costs us as we go along.

Happy Tinying.